Artisans in Australia have a plethora of options when it comes to candle wax. Whether you’re a seasoned candle maker or just starting out, understanding the different types of candle wax available is essential in creating beautiful, high-quality candles. In this article, we will explore the various candle wax options, discuss the Australian wax market, provide tips for selecting the right wax, delve into the impact of wax choice on candle performance, and highlight safety considerations when working with wax.

Understanding Different Types of Candle Wax

Paraffin Wax: A Popular Choice

Paraffin wax is one of the most commonly used waxes in candle making. Candle wax Australia is derived from petroleum and is known for its affordability and versatility. Paraffin wax is available in various melting points, making it suitable for a wide range of candle styles and purposes. Its ability to hold a fragrance well and produce vibrant colors make it a popular choice among artisans.

One interesting fact about paraffin wax is that it has been used in candle making for centuries, dating back to the 1850s when it was first commercially produced. Its long history in the industry has solidified its reputation as a reliable and consistent wax for candle makers worldwide. In addition, paraffin wax is known for its excellent scent throw, meaning it can disperse fragrance effectively throughout a room when the candle is lit.

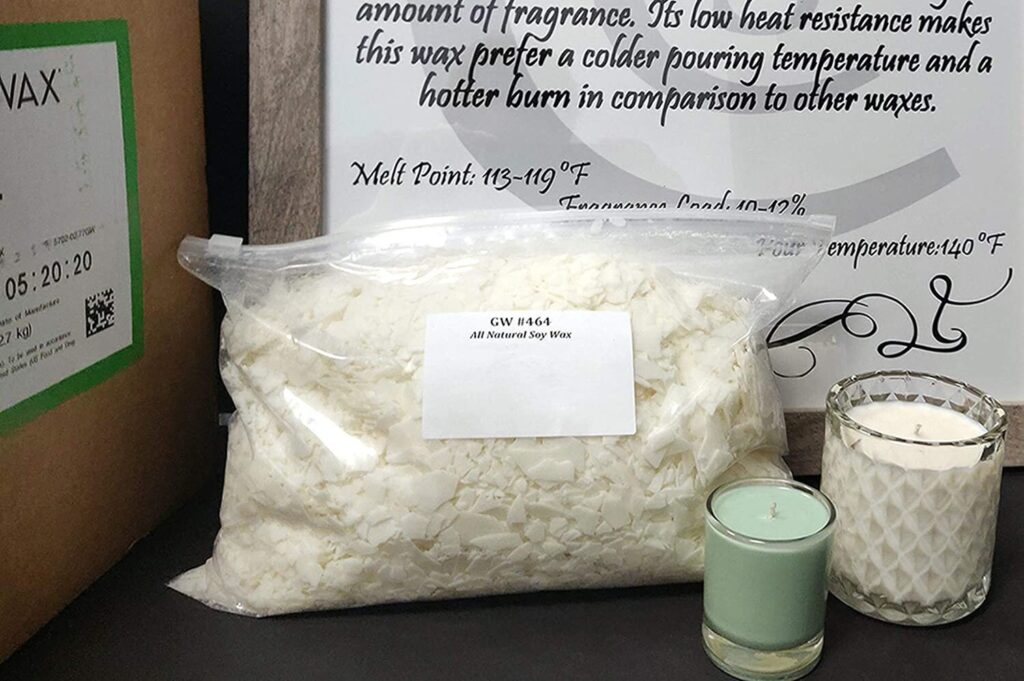

Soy Wax: An Eco-Friendly Alternative

Soy wax is a natural and renewable option that has gained popularity in recent years. Made from soybean oil, this wax is biodegradable and has a lower carbon footprint compared to paraffin wax. Soy candles burn cleaner and produce less soot, making them a healthier choice for both individuals and the environment. Additionally, soy wax has excellent fragrance throw capabilities.

One fascinating aspect of soy wax is its origins in agriculture. Soybeans, the raw material for soy wax, are a sustainable crop that supports farmers and promotes eco-friendly practices. The process of extracting soy wax involves minimal processing and is considered a more environmentally friendly alternative to traditional paraffin wax. This has led to a surge in demand for soy wax candles among consumers who prioritize sustainability and natural products.

Beeswax: The Natural Option

For those seeking a completely natural option, beeswax is an excellent choice. Beeswax is produced by bees and offers a warm, honey-like scent when burned. It is known for its long burn time and beautiful, natural golden color. However, beeswax can be more expensive than other wax types and may require additional expertise and care when working with it.

One remarkable characteristic of beeswax is its natural air-purifying properties. When beeswax candles are burned, they release negative ions that can help neutralize pollutants in the air, promoting a cleaner and healthier indoor environment. This unique feature has made beeswax candles a popular choice for individuals looking to enhance the ambiance of their living spaces while also enjoying the benefits of natural air purification.

The Australian Wax Market: An Overview

Australia has a thriving wax market with several key players contributing to its growth. Companies such as Waxes Pty Ltd, Candle Creations, and Aussie Beeswax Pty Ltd offer a wide range of high-quality waxes, catering to the diverse needs of artisans. These companies provide reliable and consistent products, ensuring that artisans can create candles with confidence.

Moreover, the Australian wax market is not only limited to traditional waxes like paraffin and beeswax. There is a growing interest in unique and exotic waxes such as palm wax and bayberry wax, which offer distinct characteristics and benefits for candle making. Artisans are experimenting with these unconventional waxes to create candles that stand out in terms of appearance and performance.

Key Players in the Australian Wax Market

In addition to the established companies, a new wave of boutique wax suppliers is emerging in the Australian market. These small-scale producers focus on handcrafted, small-batch waxes that appeal to niche markets seeking artisanal products. By offering limited edition waxes and personalized services, these boutique suppliers are adding a touch of exclusivity to the wax market, attracting discerning customers looking for unique candle-making materials.

Trends and Developments in the Wax Industry

The wax industry in Australia is constantly evolving to meet the demands of artisans and consumers. One notable trend is the increasing demand for eco-friendly waxes, such as soy wax and beeswax. As consumers become more conscious of their environmental impact, the popularity of these sustainable wax options continues to rise. Additionally, the use of custom wax blends to create unique and innovative candle creations is another trend shaping the industry.

Furthermore, technological advancements are playing a significant role in the wax industry, with the introduction of automated wax melting and blending systems. These cutting-edge technologies streamline the production process, ensuring consistency in wax quality and reducing production times. By embracing automation, wax manufacturers are able to meet the growing demand for high-quality waxes while optimizing their operations for efficiency and scalability.

Choosing the Right Wax for Your Artisanal Needs

Factors to Consider When Selecting Wax

When choosing wax for your artisanal needs, several factors should be taken into consideration. These include the type of candle you want to create, your target audience, desired fragrance strength, and budget. Each wax type has its own unique characteristics that can enhance or limit certain candle-making techniques. By evaluating these factors, you can select the perfect wax that meets your specific requirements.

Furthermore, it’s important to consider the melting point of the wax you choose. Different waxes have different melting points, which can impact the burn time and overall performance of your candles. For example, soy wax has a lower melting point compared to paraffin wax, resulting in a longer-lasting candle that disperses fragrance effectively. Understanding the melting point of wax can help you create candles that burn evenly and efficiently.

Customizing Wax Mixes for Unique Creations

One of the benefits of being an artisan is the ability to experiment and create unique candle designs. By blending different types of wax, you can achieve custom mixes that suit your creative vision. For example, a blend of soy and beeswax can offer the best of both worlds – the eco-friendliness of soy and the luxurious scent of beeswax. Customizing wax mixes opens up endless possibilities and allows you to differentiate your products in a competitive market.

Moreover, experimenting with additives such as color dyes, essential oils, or botanicals can further enhance the uniqueness of your candles. Adding dried flowers or herbs to your wax mix not only creates visually appealing candles but also introduces natural elements that appeal to eco-conscious consumers. Customizing wax mixes with creative additives can elevate your candles from simple home decor items to artisanal pieces of art.

The Impact of Wax Choice on Candle Performance

Burn Time and Scent Throw: How Wax Plays a Role

Wax choice plays a crucial role in determining the burn time and scent throw of a candle. The melting point of the wax directly affects how quickly the candle will burn. Waxes with a higher melting point tend to have longer burn times, while lower melting point waxes burn faster. Additionally, the type of wax can impact the scent throw – how well the candle fragrance spreads throughout a space. Some waxes have better scent throw capabilities, ensuring a delightful sensory experience for customers.

Furthermore, the source of the wax can also influence the overall performance of the candle. Soy wax, derived from soybean oil, is known for its clean burn and excellent scent throw. On the other hand, palm wax, made from palm oil, has a unique crystalline appearance when solidified, adding an artistic touch to candles.

The Influence of Wax on Candle Appearance

Not only does wax choice affect the performance of a candle, but it also contributes to its visual appeal. Different waxes produce distinct colors and textures when solidified. Beeswax, for example, has a natural golden hue that adds warmth to candles. Paraffin wax allows for vibrant dye colors, resulting in eye-catching creations. Considering the desired appearance of your candles and how different waxes can enhance their aesthetic is crucial in creating visually appealing products.

In addition to color and texture, the type of wax used can also affect the overall design possibilities for candles. Soy wax, being soft and pliable, is ideal for creating intricate carved or molded candles. In contrast, beeswax, with its natural stiffness, is perfect for rolled or twisted candle designs that hold their shape well. Understanding the unique characteristics of each wax type can open up a world of creative possibilities for candle makers.

Safety Considerations When Working with Wax

Handling and Storage of Candle Wax

When working with candle wax, it’s important to prioritize safety. Proper handling and storage of wax can prevent accidents and ensure a safe working environment. Always follow the manufacturer’s guidelines for handling and storage instructions, such as maintaining temperatures within recommended ranges and using appropriate containers to store wax. By taking these precautions, you can minimize risks and create a safe workspace.

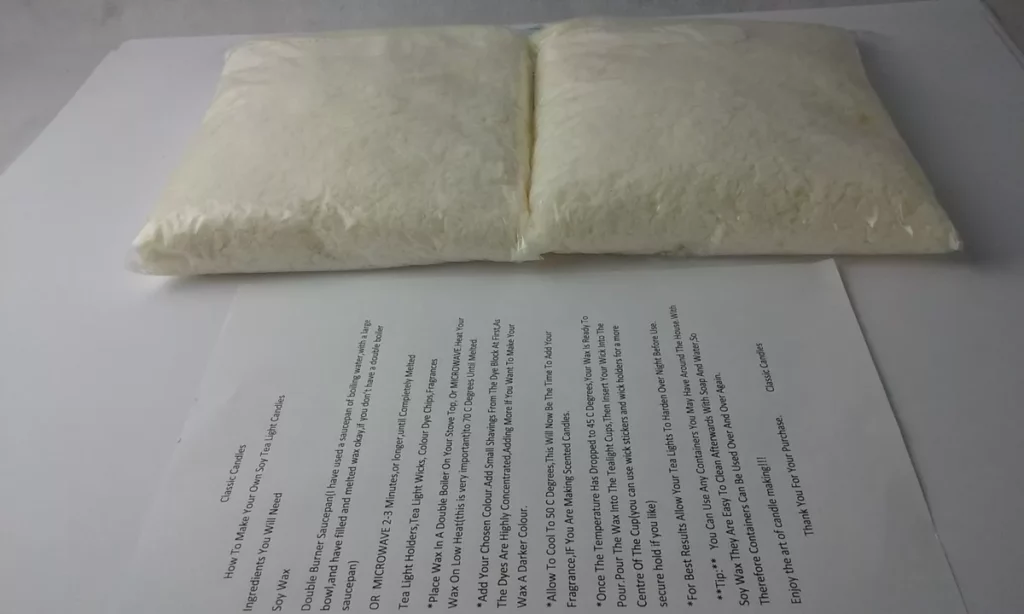

Safe Melting and Pouring Techniques

The process of melting and pouring wax should also be done with caution. It is crucial to use a designated melting pot and a double boiler setup to minimize the risk of the wax catching fire. Avoid overheating the wax, as this can lead to hot wax spills or even a fire hazard. When pouring the wax, ensure that you have a stable surface and protective equipment, such as heat-resistant gloves, to prevent burns. Following proper melting and pouring techniques is essential for both your safety and the quality of your candles.

Furthermore, it’s important to consider the type of wax you are working with. Different waxes have different melting points and handling requirements. For example, soy wax has a lower melting point compared to paraffin wax, so it requires less heat during the melting process. Beeswax, on the other hand, has a higher melting point and may require a longer melting time. Understanding the specific characteristics of the wax you are using will help you determine the appropriate melting and pouring techniques.

Additionally, ventilation is a crucial aspect of working with wax. Wax can release fumes when heated, which may be harmful if inhaled in large quantities. Ensure that your workspace is well-ventilated to minimize the concentration of fumes. If necessary, use a fume hood or work near an open window to allow for proper air circulation. Taking these measures will help protect your respiratory system and maintain a safe working environment.

In conclusion, exploring candle wax options is an integral part of the candle-making process for artisans in Australia. From paraffin wax to soy wax and beeswax, each type offers unique properties and benefits. Considering factors such as candle performance, appearance, and eco-friendliness aids in selecting the right wax for your artisanal needs. By staying abreast of market trends and practicing proper safety measures, artisans can create exquisite candles that delight their customers while making a positive impact on the environment.